Introduction to Production Process of Animal Feed and Poultry Feed

animal feed and poultry feed production process involves a series of critical steps to ensure nutritional quality and safety. This section explains how feed mills transform raw materials into balanced diets for livestock.

Making animal feed is like cooking for a huge farm party! Factories mix ingredients, shape them into pellets, and check quality – just like you’d bake cookies but for cows and chickens. Let’s break it down step by step.

Steps and Equipment Used in Production Process of Animal Feed

1. Picking the Ingredients (Feed Formulation)

What’s this?

Experts choose stuff like corn, soybeans, and vitamins. It’s like making a shopping list for a super-healthy meal.

Why it matters?

Chickens need more protein. Cows need extra fiber. Good recipes = healthy animals!

2. Crushing the Good Stuff (Grinding)

What happens?

Big machines smash grains into powder – like turning wheat into flour for pancakes!

Machines used:

- Hammer mills (loud crushers)

- Roller mills (gentle crushers)

3. Mixing

The secret:

Mix powders until every handful has the same nutrients. Imagine blending flour and sugar perfectly for cookies!

Machines:

- Batch mixers (for small batches)

- Continuous mixers (non-stop blending)

4. Pelleting

How it works:

Steam softens the mix, then presses into dry pellets – like shaping pasta!

Differences in Poultry Feed Manufacturing

Chicken feed gets special treatment!

- Heat treatment: Oven-like machines kill germs (Salmonella is a big worry)

- Tiny pellets: Sized for chicken beaks – no bigger than a pea!

Machines: Pellet mills (big pasta makers)

5. Cooling

Why?

Hot pellets get moldy. Coolers blow air through them – like cooling cookies on a rack!

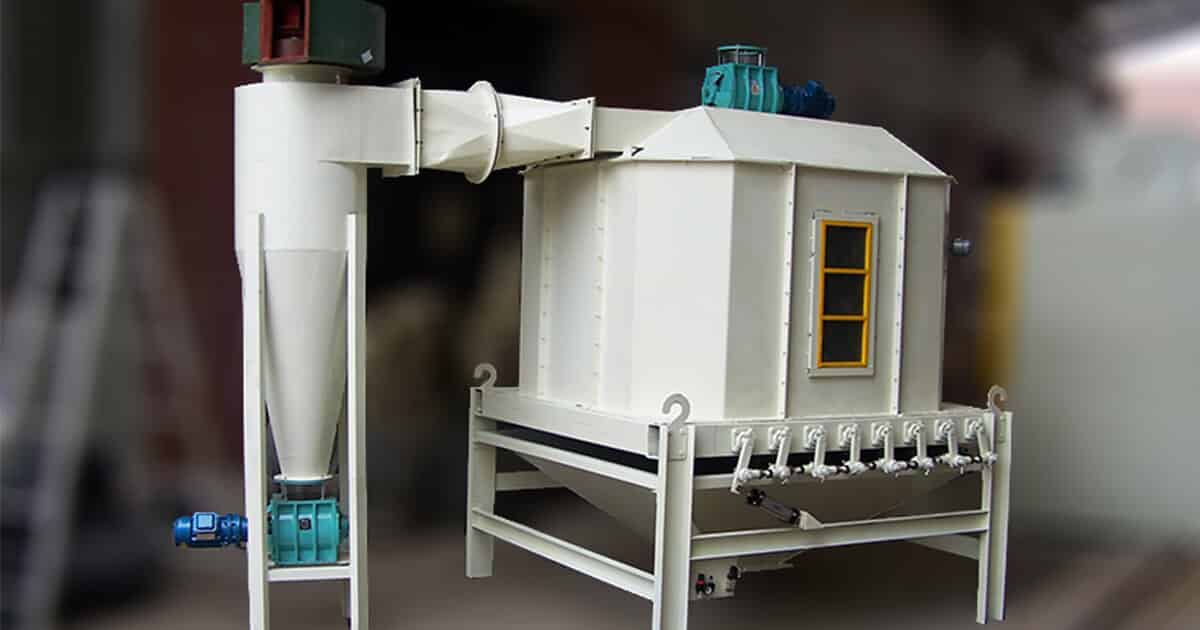

Machine name: Counterflow cooler

6. Packaging

Fun fact:

Machines weigh and seal bags faster than you pack lunch!

7. Quality Control

What they test:

- Nutrients (like checking vitamin labels)

- Germs (especially in chicken feed)

- Pellet hardness (no crumbles!)

For poultry feed:

- Salmonella tests every Monday

- Moisture under 12% (stops mold)

Top Tips for Better Feed Production

Keep Machines Clean

Simple trick: Wipe mixers after each batch – like washing your blender!

Train Workers Well

Real example:

“John forgot gloves last week. Now he knows – safety first!”

Update Recipes

New idea: Add seaweed to chicken feed for healthier eggs!

The Role of Mixing in Feed Manufacturing Process

Why is mixing important in the animal feed production steps and poultry feed pellet manufacturing? If you don’t mix pancake batter, you get flour lumps. Same with animal feed! Good mixing = every bite is perfect.

Understanding the Role of Pelleting in Feed Manufacturing Process

Pelleting in poultry feed pellet production is a pivotal process that enhances the efficiency, digestibility, and management of animal feeds.

Final Thoughts

By following these steps, factories make healthy meals for animals. Remember: Crush grains, mix well, press pellets, test everything. With good feed mill equipment for animal feed, farmers keep their cows, pigs, and chickens happy and strong.